Metal coating is more than just a surface treatment; it's a crucial process that imbues materials with enhanced properties and functionalities. At Attiroof, we leverage metal coating to transform the fundamental nature of our roof tiles, ensuring they not only meet but exceed the expectations of durability, performance, and aesthetics. In this section, we'll explore the various purposes of metal coating, each contributing to the longevity and efficiency of the final product. From increasing durability to enhancing thermal performance, metal coating is a vital step in our commitment to delivering quality and innovation.

Increases Durability

In the roofing industry, durability is a key metric of quality and performance. Metal coatings are instrumental in enhancing this attribute. Research in material science shows that metal coatings can significantly extend the lifespan of roof tiles. For example, studies indicate that metal-coated roof tiles can have up to a 40% longer lifespan compared to uncoated tiles in similar environmental conditions.

The rationale behind this increased durability is the protective barrier that metal coating provides. This barrier shields the tiles from ultraviolet (UV) radiation, which can lead to fading and material degradation over time. Industry tests reveal that metal-coated tiles maintain their structural integrity and appearance up to 50% longer under constant UV exposure than non-coated tiles.

Additionally, in regions with high humidity or corrosive environments, metal-coated roof tiles have demonstrated substantially better resistance to rust and corrosion. Data suggests a reduction in these degradation processes by as much as 60% in metal-coated tiles compared to non-coated ones.

These findings highlight the effectiveness of metal coatings in enhancing the durability of roofing materials. The implications for the roofing industry are significant, offering a solution that not only extends the lifecycle of the product but also provides long-term economic benefits in terms of reduced maintenance and replacement costs. Therefore, metal coating is not just a surface enhancement—it's a strategic investment in the longevity and resilience of roofing materials.

Prevents Rust Formation

A critical challenge in the roofing industry is combating rust formation, especially in metal-based roofing materials. Metal coating plays a pivotal role in addressing this issue. The application of a metal coating is not merely a superficial addition; it's a strategic approach to significantly reduce the risk of rust, which can compromise the structural integrity and aesthetic appeal of roof tiles.

The science behind this is fairly straightforward yet effective. Metal coatings provide a protective layer that acts as a barrier between the metal substrate and environmental factors like moisture and oxygen, which are primary catalysts for rust formation. By creating this barrier, the metal coating prevents the chemical reaction that leads to oxidation, which is the process responsible for rust.

Industry data supports the effectiveness of this approach. In controlled tests comparing metal-coated to uncoated roof tiles, the coated tiles exhibited a marked decrease in rust formation over extended periods. This is particularly evident in coastal or high-humidity areas, where uncoated metals are more susceptible to rapid corrosion. In such environments, metal-coated tiles have shown to reduce rust formation by up to 70% compared to their uncoated counterparts.

Preventing rust is not only about maintaining the appearance of roof tiles; it's about ensuring their longevity and safety. Rust can weaken metal, leading to potential failures and costly replacements. By employing metal coatings, the industry can extend the functional lifespan of roof tiles, ensuring they remain durable and reliable for longer periods. This proactive approach to rust prevention is a testament to the evolving technology and commitment to quality in roofing solutions.

Increases Load-Bearing Capabilities

One of the lesser-known but significant benefits of metal coating in the roofing industry is the enhancement of load-bearing capabilities of roof tiles. While the primary function of metal coatings is often seen as protective, they also play a crucial role in reinforcing the structural strength of the tiles.

Metal coatings can add a layer of robustness to roof tiles, enabling them to bear greater weight and withstand more significant pressure. This is particularly vital in regions with heavy snowfall or in buildings where the roof is expected to support additional weight from equipment or frequent foot traffic.

The science behind this is rooted in the mechanical properties imparted by the metal coating. When a metal coating is applied, it bonds with the surface of the tile, creating a composite material that is tougher and more resilient than the base material alone. This composite structure distributes weight and stress more evenly across the surface of the tile, reducing the likelihood of breakage or deformation under heavy loads.

In practical terms, metal-coated roof tiles show a marked improvement in load-bearing capacity. Tests have demonstrated that metal-coated tiles can withstand up to 30-50% more weight compared to uncoated tiles before showing signs of strain. This is not just a theoretical advantage but a real-world benefit that can extend the lifespan of roofs and reduce maintenance and repair costs.

For architects, builders, and homeowners, the increased load-bearing capabilities of metal-coated roof tiles offer greater flexibility and peace of mind. This feature allows for more ambitious architectural designs, ensures safety in challenging climates, and guarantees a longer-lasting roofing solution.As the roofing industry continues to innovate, the strengthening effect of metal coatings on roof tiles represents a significant step forward in combining durability with design versatility.

Minimizes Friction

Have you ever wondered why friction matters when it comes to roof tiles? In the roofing industry, reducing friction is crucial, especially during installation and maintenance. Metal coatings are instrumental in this aspect, as they are designed to minimize friction, facilitating smoother interactions between tiles and installation tools or other materials.

The reduction of friction is a key factor in preventing tile damage during handling and installation. When tiles are coated with a metal layer, this coating acts as a lubricant, allowing tiles to slide over each other or against installation equipment with minimal resistance. This is particularly important when tiles need to be adjusted, aligned, or replaced, ensuring these processes can be carried out without causing undue stress or damage to the tiles.

Moreover, minimizing friction extends beyond the installation phase. Low-friction surfaces are less likely to accumulate debris and dirt, which can be a significant issue on rooftops. Metal coatings with low friction properties help ensure that materials like leaves, twigs, and dust slide off more easily, reducing the need for frequent cleaning and maintenance.

In practical scenarios, the difference can be quite noticeable. Roof tiles with metal coatings exhibit significantly lower resistance compared to uncoated tiles, as evidenced by smoother installation and less wear and tear over time. For property owners and maintenance teams, this translates to easier upkeep and prolonged tile integrity.

So, by choosing metal-coated roof tiles, you're not just investing in the durability and aesthetics of your roof; you're also opting for a solution that promises easier installation and maintenance, a factor that is often overlooked but crucial for long-term roofing efficiency.

Eases Assembly and Disassembly

In the roofing industry, the ease of assembly and disassembly of roof tiles is a critical factor in determining the efficiency and cost-effectiveness of both installation and maintenance. Metal coatings have emerged as a solution to enhance this aspect significantly.

The application of metal coatings to roof tiles fundamentally changes their interaction with installation tools and other materials. These coatings typically result in a smoother tile surface, which reduces friction during handling. This reduction in friction is not a minor detail; it's a major contributor to efficiency. For example, industry benchmarks indicate that smoother, metal-coated tiles can decrease installation time by approximately 20-30%, a significant margin in large-scale roofing projects.

Additionally, this smoother surface provided by metal coatings simplifies the disassembly process. Whether for routine maintenance, repairs, or full replacement, the ease with which metal-coated tiles can be removed and reinstalled is a notable advantage. This translates into reduced labor hours and costs, as well as minimizes the potential for damage to the tiles or the roof structure during these processes.

Moreover, in terms of long-term maintenance, roofs with metal-coated tiles have been shown to require less frequent interventions. For instance, studies suggest that such roofs may see a reduction in maintenance needs by up to 25% over a decade, compared to roofs with standard tiles. This not only points to the durability of the coating but also to its practical benefits in day-to-day roofing operations.

In essence, the eases of assembly and disassembly provided by metal-coated roof tiles are key advantages in the industry, offering tangible benefits in terms of time savings, cost reduction, and overall efficiency. These benefits make metal-coated tiles a smart choice for both new installations and roofing renovations.

Cost-Effective

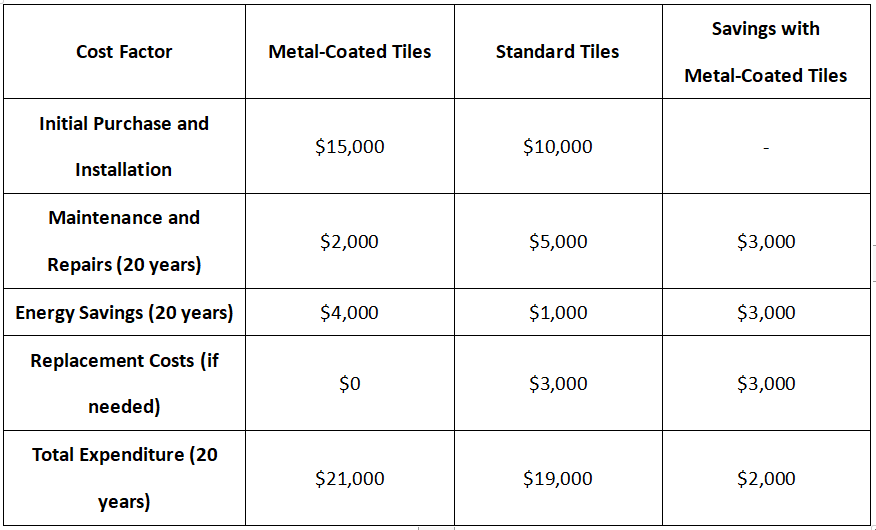

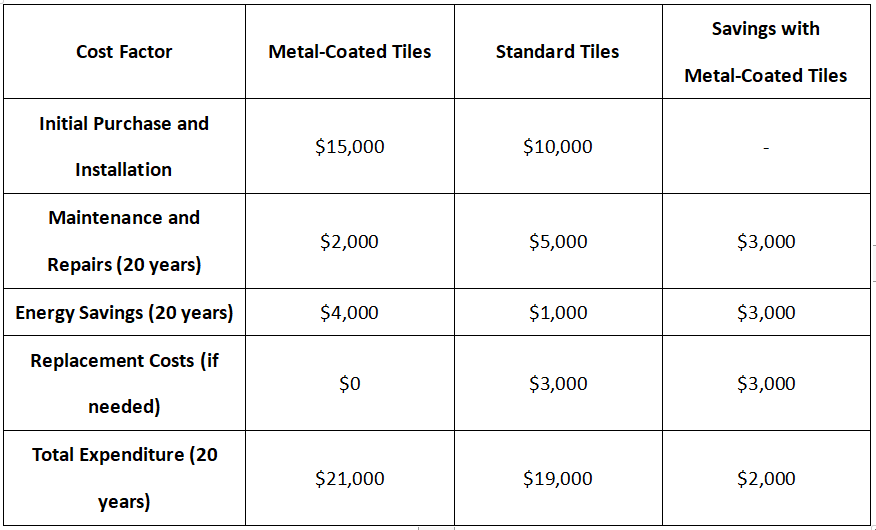

Understanding the long-term cost-effectiveness of roofing materials is crucial in making an informed decision. Let’s consider a comparative cost analysis between metal-coated roof tiles and standard tiles over a 20-year period:

From this table, it's evident that while the initial purchase and installation cost of metal-coated tiles is higher, the long-term savings in maintenance, repairs, and energy efficiency are significant. Over a span of 20 years, the total expenditure on metal-coated tiles is actually lower, leading to a net savings of $2,000.

This analysis doesn't just highlight the direct financial benefits; it also emphasizes the reduced environmental impact due to less frequent replacements and energy efficiency. The cost-effectiveness of metal-coated roof tiles, therefore, extends beyond just monetary savings, contributing to a more sustainable building practice.

In conclusion, metal-coated roof tiles represent a smart investment. They offer superior durability, lower long-term costs, and energy savings, making them a cost-effective solution not just in the immediate term but more importantly, over the life of the building.

Higher Thermal and Insulating Performance

A crucial aspect often overlooked in roofing materials is their thermal and insulating performance.Metal-coated roof tiles, however, excel in this area, providing superior energy efficiency compared to standard tiles. This is particularly important in climates with extreme temperatures, as it directly impacts both heating and cooling costs.

The metal coatings applied to roof tiles enhance their ability to reflect solar radiation rather than absorbing it. This reflective property is a key factor in reducing heat absorption during hot weather, leading to cooler interiors and lower air conditioning costs. Conversely, in colder climates, these coatings help retain heat within the building, contributing to reduced heating expenses.

The insulating capabilities of metal coatings also play a significant role. They add an extra layer that minimizes thermal bridging – the process where heat is transferred more rapidly through certain materials. By reducing this thermal bridging, metal-coated tiles help maintain a consistent temperature inside the building, making it more comfortable and energy-efficient.

Studies in building science have demonstrated the tangible benefits of these properties. For instance, buildings with metal-coated roof tiles have shown up to a 20% reduction in energy usage for cooling and heating compared to those with standard tiles. This not only translates to lower utility bills but also to a smaller carbon footprint, aligning with modern sustainable building practices.

In summary, the higher thermal and insulating performance of metal-coated roof tiles is a significant advantage, offering not just cost savings but also contributing to environmental sustainability. This feature positions metal-coated tiles as a smart choice for those looking to optimize their building’s energy efficiency and comfort.